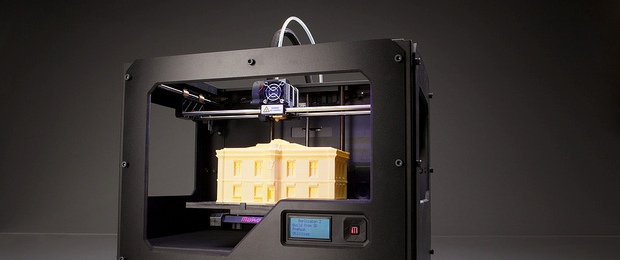

There is nothing new about 3D printer technology. In fact, it has been used for over thirty years in industry for constructing prototypes and scale models. What is new is its breakthrough into the consumer environment. Until now, 3D printers were far too expensive, meaning that their qualities could only be harnessed by companies with very specific needs. The possibility of mass-marketing these devices has sparked an interest in improving them and researching potential advances.

There is still plenty of room for improving 3D printers. The fact that this is such a recent topic means some details get lost amidst the tidal wave of information about the subject. The idea behind this article is to present six curious facts about 3D printing that you might not have heard of.

The use of domestic waste to load 3D printers

3D printers use certain types of plastic, mainly ABS and, to a lesser degree, PLA, which are normally expensive. The price of one load ranges from 30 to 60 dollars (23 to 46 euros). On the other hand, every household dumps kilos of plastic waste into the environment (albeit after having separated it for recycling) every week.

Scientists at Michigan Technological University are building a machine capable of recycling household waste containing plastic, namely everything from milk bottles to some toys, and converting it into material suitable for use in 3D printers. The invention has been called Filabot and it will enable part of the waste generated by a household to be reused, saving us from having to purchase the ABS plastic used in these printers. The method has yet to be perfected, however, as the performance level of the material produced by Filabot does not match that provided by the manufacturers’ refills.

Two operational approaches: two prices

3D printing can be done in different ways. One of the most popular is stereolithography. This technique is based on a light-sensitive photopolymer, which is used as the raw material. Ultraviolet radiation is applied in layers as the material is released. In this way each new layer is solidified and bonded to the previous one, while being made ready to receive the next one.

The main drawback of this method is its high price. This has given rise to FDM rapid prototyping technology as an alternative, which is somewhat less accurate, but cheaper. It consists of a jet of material that emerges through a nozzle in liquid form due to the nozzle’s high temperature. The plastic hardens the instant it leaves the nozzle.

Cheap high-quality 3D printing

Although FDM technology is the cheap option, a number of researchers are working on improving the results of 3D printing without sending the costs through the roof. The FORM 1 project, backed by Kickstarter, opts for a printer that works using stereolithography, but at a far lower cost than we have been used to up until now. Its creators have now completed the test phase and the device has gone into production.

3D printing is being applied to health care

A joint research project involving the Weill Cornell Medical College and the Bioengineering Department of Cornell University has successfully developed an identical replica of a human ear thanks to 3D printing. Injectable gels made up of living cells were used to do so. This is just one example of this technology being used for applications above and beyond the purely commercial.

Experiments are being carried out on the construction of other human body parts using 3D printers. Companies such as Autodesk and Organova have begun researching into using these devices to create human tissue. The most recent development is that 3D printing could be used to create human organs, which would represent an extremely important breakthrough for the transplant sector.

A driving force behind the transformation of business relations

3D printing puts a different slant on the ‘do it yourself’ philosophy. In some cases, users/consumes can create their own objects or make spare parts. Although not always easy, initiatives exist to help make this idea a reality. The website thingiverse.com has open-source 3D models available free of charge.

Manufacturers themselves may also contribute to this trend. An example of how this is happening is that of Teenage Engineering. This company, which sells a synthesizer, has published the CAD diagrams on its website so that the users of their product can print out spare parts in 3D instead of paying a high price for having them delivered.

The evolution of the 3D printer is… 4D

A team of MIT researchers is working with self-assembling structures. The process has been named ‘Self Assembly’ and really does sound like science fiction. Nonetheless, the scientists are already running tests. It involves arranging the particles of a material in such a way that they include the design of a specific structure. When immersed in water, the composition of the material reacts, resulting in the appearance of the planned object.