The Contour Crafting project is using 3D printing techniques to build houses, with the aim of making conventional construction methods a thing of the past.

About 1 billion people live in miserable conditions, in huts or shacks patched up with cloths and scrap. This is the figure quoted by industrial engineering professor Behrokh Khoshnevis, the driving force behind Contour Crafting, a project aimed at building houses using 3D printing techniques. The technology enables a house of 2,500 square metres to be built in 20 hours, which is not only a record, but raises hopes of reducing habitability problems in the world.

Overcrowded slums and suburbs are a hive of unsanitary conditions, despair and crime. However, legislative or administrative measures are not enough to curb these problems because there is a substantial underlying matter: the simple physical inability to construct buildings in which house large parts of the population.

Professor Khoshnevis, from the University of Southern California, blames conventional construction methods, calling them slow and dangerous, while associating them with intensive labour needs and corruption. Additionally, the task of constructing a building generates a large amount of waste, including gas emissions to the atmosphere.

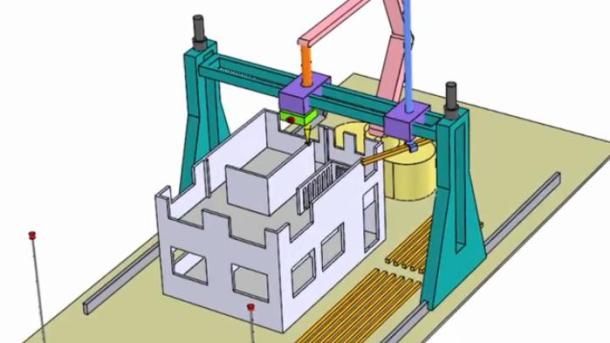

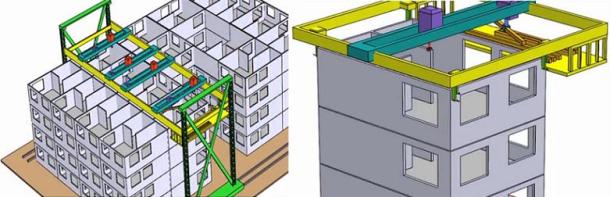

The Contour Crafting project has set itself the goal of accelerating the construction process drawing from CAD/CAM industrial manufacturing, the same model that 3D printers use. The architectural design is done entirely on a digital program which, once completed, is sent to the machine so production can start.

A house in under 20 hours

Contour Crafting machines are basically large 3D printers that operate with a wide range of materials, not only ABS plastic, which is commonly used in these machines. They mostly use cement – modified so that it can endure the hectic pace of this building system – which is deposited layer by layer through a nozzle.

Contour Crafting has the capacity to build entire neighbourhoods at a low cost, as it saves on materials and labour. Meanwhile, the design of each house or each building can be easily modified, as it is contained in a digital file. The electrical, plumbing or heating systems can be installed while the building is under construction. When it is finished, the machines can also paint the walls. In short, a house of 2,500 square metres can be ready in 20 hours.

The project works with large robots that can be assembled in several ways: one for a detached house, another for a row of houses or a building of various heights, which would require progressively lifting the machines. If most objects these days are produced automatically, why wouldn’t we be able to do the same with houses?

[youtube]http://www.youtube.com/watch?v=-yv-IWdSdns[/youtube]