We are aware that water is essential to most life forms known to man, including humans, but it is also one of the main enemies in the life of materials subjected to inclement weather or extreme conditions. Some products on the market have hydrophobic properties designed to waterproof surfaces and prevent the action of water. But nothing compares to the technology of Ultra-Ever Dry.

UltraTech International, introduces Ultra-Ever Dry, a product with superhydrophobic –water– and oleophobic –hydrocarbon– properties whose technology enables it to repel virtually any liquid. Water, oil and even viscous substances such as mud or liquid cement are completely repelled from any surface. Once the hydrophobic and oleophobic product has been sprayed on the surface, it creates an air pocket which, thanks to the nanostructure of the product’s particles, prevents any liquid that spills on it, regardless of the amount or viscosity, from penetrating or adhering to the pores of the base material.

To achieve the properties of this revolutionary product, UltraTech International researchers have used patented nanotechnology to prevent adhesion to water, oil and other liquids, but have also introduced insuperable resistance to abrasion and friction, which, unlike previous technologies, can be used on any type of surfaces requiring greater durability and resistance.

Nanotechnology to repel liquids

Superhydrophobic surfaces are based on the lotus effect, also known as the lotus anti-adherent effect, discovered in the seventies through microscopic observation of the natural hydrophobic properties of the leaves of the lotus flower. In the mid nineties Wilhelm Barthlott developed and patented the principle registered as the «lotus effect» through the use of nanotechnology, which is the basis of all surfaces with hydrophobic characteristics.

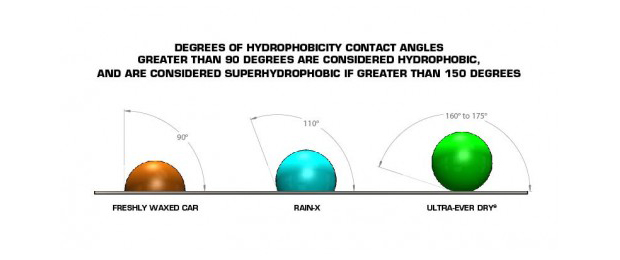

Unlike hydrophobicity which is a chemical property, superhydrophobia is primarily physical. According to Julius Marmur’s investigations in the field of molecular biology, there are two basic principles underlying superhydrophobicity: the first is to produce a contact angle between the water droplet and the surface, and the second principle is to ensure that the angle has the greatest inclination possible in order to distance the drop as far away as possible from the surface. So if the contact angle ranges between 90 and 150 degrees, we obtain hydrophobic properties that repel water. However, with a contact angle greater than 150 degrees, at nanoscale the surface tension effect of water is amplified making it impossible to wet the surface, and superhydrophobic characteristics are thus obtained.

Possible applications of this revolutionary coating

On surfaces where the product is sprayed, the contact angle generated by the nanoscale structure of this product maintains a microscopic film of air over the superhydrophobic dust nanostructure, producing a change in the basic water-solid interface that prevents the liquid interacting with the surface. This basic characteristic gives the product antibacterial, anticorrosive, antifreeze, self-cleaning and water resistant qualities that are of great interesting for industry and construction, where machinery, tools and work equipment are exposed to extreme situations and to the action of water or other substances.

[youtube]http://www.youtube.com/watch?feature=player_embedded&v=IPM8OR6W6WE[/youtube]

Since superhydrophobic surfaces are more resistant and hygienic, adhesion of grease is avoided, as is the corrosion of metallic materials by the action of salt water or lime, increasing the material’s durability. Moreover, since it is impossible to wet the surface, water cannot condense and ice cannot be formed on the surface in extreme climates. And that is not all, its characteristics reduce water friction on the surface, providing significant improvements in the field of hydrodynamics.

Another illustrative example of the use of superhydrophobic surfaces is that, because of their water repellent characteristics, they are perfect insulators for preventing damage to electrical or electronic equipment from accidental contact with water, as well as being immune to dirt, because they prevent the adhesion of any dust or dirt molecules on any kind of surface. However, a completely transparent product has not yet been obtained and so it is not recommended for use on surfaces such as glass or lens, because it decreases visibility and makes it harder to capture good images.

These examples illustrate the endless direct applications of the lotus effect in the industrial sector, but its application on fabrics could revolutionize the fashion industry by manufacturing clothes that are impossible to stain and which would therefore not require the use of the washing machine. It would also serve as a barrier to prevent graffiti on the walls and street furniture or public spaces and as an antibacterial surface in biomedicine. The truth is that a lot remains to be said in the coming years about this revolutionary product thanks to the latest advances in nanotechnology, increasing the life of almost any surface, not to mention avoiding unsightly stains on our favourite pair of trousers.

Images | via UltraTech International